- Home Page

- Company Profile

-

Our Products

- Industrial Packaging Machine

- pouch packing machine

- Collar Type Pouch Packing Machine

- Tea Pouch Packing Machine

- Single Head Automatic Packing Machine

- Pouch Filling Machine

- Fully Automatic Pouch Packing Machine

- 4 Head Linear Weight Filler

- Namkeen Packing Machine

- FFS Machine

- pneumatice Automatic Pouch Packing Machine

- Industrial Packing Machine

- Food Packaging Machine

- Milk Powder Packaging Machine

- Toys Gift Packing Machine

- Pepsi Pouch Packing Machine

- Pouch Packing Machine

- Rice Packaging Machines

- ORS Powder Pouch Packing Machine

- Kurkure Packing Machine

- BESAN POUCH PACKING MACHINE

- Granule Pouch Packing Machine

- Weighing Filling Machine For Spices

- Volumetric Cup Filler Machine

- Spice Pouch Packing Machine

- Flour Packing Machine

- Seed Packaging Machine

- Tea Pouch Packing Machine

- Pulses Packing Machine

- Tea Packing Machine

- Pneumatic Pouch Packing Machine

- Automatic Pouch Packing Machines

- Fully pneumatic pouch packing machine

- Packaging Machine

- Black Pepper Packaging Machine

- pneumatic cup filler

- Granule Pouch Packing Machine

- Cup Filler Machine

- Tea Packing Machine

- Granules Packing Machine

- Potato Chips Packing Machine

- Wafers Packing Machine

- Sugar Packing Machine

- Potato Packing Machine

- Automatic Spice Powder Pouch Packing Machine

- STAINLESS STEEL SPICES POUCH PACKING MACHINE

- Snack Packing Machine

- Ice Cream Packaging Machine

- Automatic Detergent Powder Packing Machine

- Detergent Packaging Machine

- flour packing machine

- Banana Chips Packaging Machine

- Pneumatic Packing Machine with gift conveyor

- automatic Grain Packing Machine

- Snack Packing Machines

- Potato Packing Machine

- Single Head Weigher Pouch Packing Machine

- 4 Head Linear Weight Filler

- Chilli Powder Pouch Packing Machine

- Automatic Atta Packing Machines

- Vertical Form Fill Seal Machines

- Chikki Pouch Packing Machine

- Besan Packing Machine

- Four Head Weigher Packing Machine

- Automatic Murmura Packing Machines

- jally depositor Machine

- Bhujia Sev Packing Machine

- Popcorn Packing Machine

- Makhana Packing Machine

- Automatic Tea Packaging Machine

- Murmura Packing Machine

- Salt Packaging Machine

- Cup Filler Pouch Packing Machine

- Papad Packing Machine

- Candy Packaging Machine

- Flow Wrap Packaging Machines

- Automatic Spice Packaging Machine

- Multihead Weigher Packing Machine

- Powder Filling Machine

- Liquid Packaging Machine

- Certificates

- Contact Us

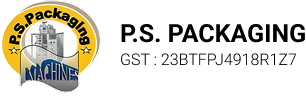

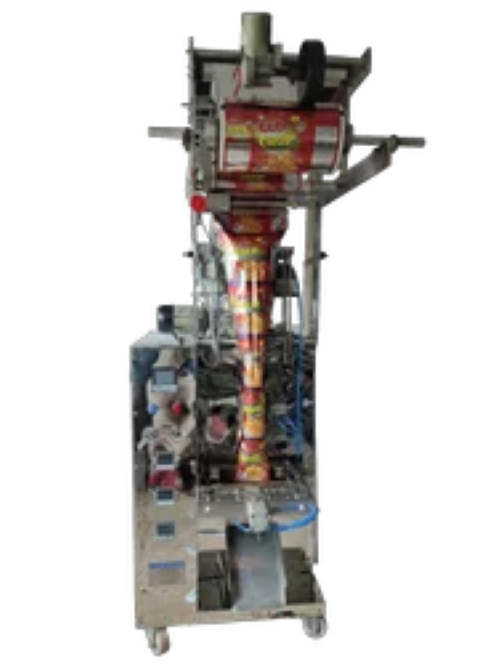

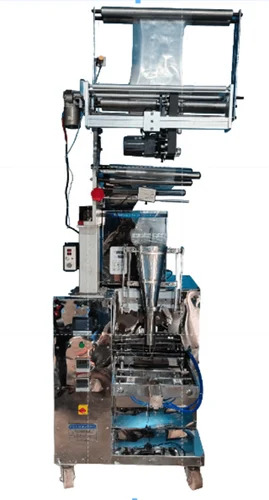

Wafers Packing Machine

145000.0 INR/Unit

Product Details:

- Application Potato wafers/chips packaging for small, medium, and family-size packs. Banana chips packing with accurate weight and minimal breakage. Tapioca and cassava chips packaging for export and domestic markets. Corn chips and nachos packing with uniform filling. Kurkure, puff snacks, and pellets packing, thanks to gentle handling

- Power Supply 5.5kw

- Filling Range 60-70

- Features High-accuracy weighing using 10-head combination technology for uniform pack weights. Gentle product handling to prevent crushing or breakage of fragile wafers and chips. Fast packing speed, suitable for medium to large-scale production. Automatic pouch forming, filling & sealing in one continuous process. Stainless-steel contact parts for hygiene and food safety.

- Usage Industrial

- Type Filling Machine

- Material Stainless Steel

- Click to view more

X

Wafers Packing Machine Price And Quantity

- 145000.0 INR/Unit

- 1 Unit

Wafers Packing Machine Product Specifications

- Stainless Steel

- 3 Horsepower (HP)

- Heat Sealing

- Silver

- PLC Control

- Industrial

- 1 year

- Electric

- High-accuracy weighing using 10-head combination technology for uniform pack weights. Gentle product handling to prevent crushing or breakage of fragile wafers and chips. Fast packing speed, suitable for medium to large-scale production. Automatic pouch forming, filling & sealing in one continuous process. Stainless-steel contact parts for hygiene and food safety.

- 60-70

- 5.5kw

- Filling Machine

- 220 Volt (v)

- Highly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

- 60-70 Pcs/hr

- Automatic

- Potato wafers/chips packaging for small, medium, and family-size packs. Banana chips packing with accurate weight and minimal breakage. Tapioca and cassava chips packaging for export and domestic markets. Corn chips and nachos packing with uniform filling. Kurkure, puff snacks, and pellets packing, thanks to gentle handling

- Other

- No

Wafers Packing Machine Trade Information

- 10 Unit Per Month

- 7 Days

Product Description

A wafers packing machine with a 10-head weigher is an advanced automatic system designed to pack delicate snacks like potato wafers, banana chips, tapioca chips, and similar light products with high speed and accuracy. The 10-head multi-head weigher gently measures the wafers using individual weighing heads, selecting the best combination to achieve the exact target weight without crushing or breaking the chips. Once weighed, the product is smoothly transferred to the packaging machine, which forms the pouch, fills the chips, seals it, and cuts it into ready-to-sell packs. The entire system ensures fast production, uniform pack weight, minimal product damage, and hygienic operation. With easy controls, stainless-steel contact parts, and stable performance, this machine is ideal for snack manufacturers seeking consistent quality and efficient mass production.

Superior Accuracy and Gentle Handling

Our wafers packing machine employs advanced 10-head combination weighing, ensuring every pack is uniform and consistent. The sophisticated mechanism gently fills and seals the snacks, dramatically reducing breakage or crushing even with delicate items like banana wafers or cassava chips. This approach ensures high-quality presentation for export and retail alike.

Efficient and Hygienic Packaging Process

With fully automatic operations, the machine forms, fills, and heat-seals each pouch seamlessly, reaching speeds suitable for large-scale production. All food contact components are stainless steel, upholding stringent hygiene standards and making cleaning straightforward. A heavy-duty construction provides durability and rust resistance, essential for demanding industrial use.

Versatile Application for Snack Producers

Designed for packing a variety of snacks-potato chips, puffs, nachos, and more-this machine supports small, medium, and family-sized packs with equal efficiency. Its capability to serve both domestic and export needs makes it a versatile choice for manufacturers looking to scale or diversify their product lines.

FAQ's of Wafers Packing Machine:

Q: How does the machine ensure uniform and accurate filling of snack packs?

A: The machine is equipped with a 10-head combination weighing system that provides precise weighing for each pack. This technology ensures all packs maintain uniform weights, reducing giveaways and enhancing packaging consistency, regardless of snack type or pack size.Q: What kind of products can be packaged using this machine?

A: The automatic wafers packing machine is suitable for potato and banana chips, cassava and tapioca chips, corn chips, nachos, kurkure, puffed snacks, and pellets. It's designed to handle various pack sizes including small, medium, and family-sized with minimal breakage and high efficiency.Q: When is this machine most beneficial for manufacturers to use?

A: The machine is ideal for medium to large-scale production environments, particularly when consistent packing speed and high accuracy are required. It suits snack producers serving retail, export, or domestic markets who need efficient, automated packaging processes.Q: Where can the wafers packing machine be installed and who supplies it?

A: This machine is designed for industrial facilities and food production plants. It is manufactured and supplied in India, offering local availability with after-sales support and a one-year warranty on parts and service.Q: What is the process for packaging snacks using this machine?

A: Snacks are loaded into the hopper, then automatically weighed, filled into pouches, and heat-sealed in a continuous process using PLC controls. The gentle handling system minimizes damage, and the stainless steel ensures the process remains sanitary from start to finish.Q: How does the machine benefit snack producers compared to manual packing?

A: Producers benefit from significantly faster packing speeds, improved pack weight accuracy, and much lower risk of product breakage. The automated process requires less manual labor, ensures food safety with rustproof materials, and meets industrial-scale production requirements with less energy consumption.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email