- Home Page

- Company Profile

-

Our Products

- Industrial Packaging Machine

- pouch packing machine

- Collar Type Pouch Packing Machine

- Tea Pouch Packing Machine

- Single Head Automatic Packing Machine

- Pouch Filling Machine

- Fully Automatic Pouch Packing Machine

- 4 Head Linear Weight Filler

- Namkeen Packing Machine

- FFS Machine

- pneumatice Automatic Pouch Packing Machine

- Industrial Packing Machine

- Food Packaging Machine

- Milk Powder Packaging Machine

- Toys Gift Packing Machine

- Pepsi Pouch Packing Machine

- Pouch Packing Machine

- Rice Packaging Machines

- ORS Powder Pouch Packing Machine

- Kurkure Packing Machine

- BESAN POUCH PACKING MACHINE

- Granule Pouch Packing Machine

- Weighing Filling Machine For Spices

- Volumetric Cup Filler Machine

- Spice Pouch Packing Machine

- Flour Packing Machine

- Seed Packaging Machine

- Tea Pouch Packing Machine

- Pulses Packing Machine

- Tea Packing Machine

- Pneumatic Pouch Packing Machine

- Automatic Pouch Packing Machines

- Fully pneumatic pouch packing machine

- Packaging Machine

- Black Pepper Packaging Machine

- Granule Pouch Packing Machine

- Cup Filler Machine

- Tea Packing Machine

- Granules Packing Machine

- Potato Chips Packing Machine

- Wafers Packing Machine

- Sugar Packing Machine

- Potato Packing Machine

- Automatic Spice Powder Pouch Packing Machine

- STAINLESS STEEL SPICES POUCH PACKING MACHINE

- Snack Packing Machine

- Ice Cream Packaging Machine

- Automatic Detergent Powder Packing Machine

- Detergent Packaging Machine

- flour packing machine

- Banana Chips Packaging Machine

- Pneumatic Packing Machine with gift conveyor

- automatic Grain Packing Machine

- Snack Packing Machines

- Potato Packing Machine

- Single Head Weigher Pouch Packing Machine

- 4 Head Linear Weight Filler

- Chilli Powder Pouch Packing Machine

- Automatic Atta Packing Machines

- Vertical Form Fill Seal Machines

- Chikki Pouch Packing Machine

- Besan Packing Machine

- Four Head Weigher Packing Machine

- Automatic Murmura Packing Machines

- jally depositor Machine

- Bhujia Sev Packing Machine

- Popcorn Packing Machine

- Makhana Packing Machine

- Automatic Tea Packaging Machine

- Murmura Packing Machine

- Salt Packaging Machine

- Cup Filler Pouch Packing Machine

- Papad Packing Machine

- Candy Packaging Machine

- Flow Wrap Packaging Machines

- Automatic Spice Packaging Machine

- Multihead Weigher Packing Machine

- Powder Filling Machine

- Liquid Packaging Machine

- Stainless Steel Soap Bar Screw Conveyor

- Certificates

- Contact Us

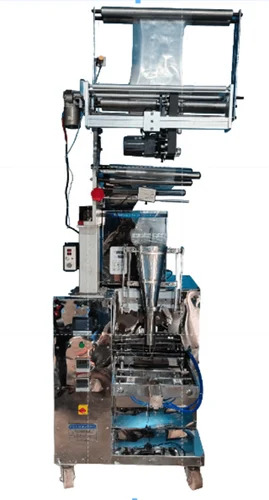

Cup Filler Machine

375000.0 INR/Piece

Product Details:

- Usage Industrial

- Filling Range 45-60

- Power Supply 50hz

- Features Volumetric cup filling system for accurate and consistent product measurement. Adjustable cup volumes to pack different weights without major changeover. Smooth and steady product flow suitable for free-flowing materials. High-speed filling capability ideal for continuous production lines. Stainless-steel contact parts for hygiene and food-grade safety. User-friendly PLC or digital control panel for easy operation and settings.

- Application Sugar packaging for small and bulk consumer pouches. Salt packing including table salt and refined salt. Grains such as rice, wheat, millets, and corn. Pulses like chana dal, moong dal, urad dal, masoor dal, etc. Tea granules including CTC tea and flavored tea. Spices (whole) like jeera, saunf, dhania seeds, and black pepper. Seeds including mustard, sesame, cumin, and various mixed seeds. Namkeen and snack ingredients such as boondi, sev variants, and small crunchy items.

- Type Filling Machine

- Material Stainless Steel

- Click to view more

X

Cup Filler Machine Price And Quantity

- 1 Piece

- 375000.0 INR/Piece

Cup Filler Machine Product Specifications

- 1 year

- No

- Heat Sealing

- Stainless Steel

- 45-60

- Filling Machine

- 50hz

- 230v Volt (v)

- Automatic

- Silver

- 400-450 Kilograms (kg)

- Volumetric cup filling system for accurate and consistent product measurement. Adjustable cup volumes to pack different weights without major changeover. Smooth and steady product flow suitable for free-flowing materials. High-speed filling capability ideal for continuous production lines. Stainless-steel contact parts for hygiene and food-grade safety. User-friendly PLC or digital control panel for easy operation and settings.

- Other

- 45-60 Pcs/hr

- Industrial

- 1000x1000 Millimeter (mm)

- Highly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

- 220 Volt (v)

- Sugar packaging for small and bulk consumer pouches. Salt packing including table salt and refined salt. Grains such as rice, wheat, millets, and corn. Pulses like chana dal, moong dal, urad dal, masoor dal, etc. Tea granules including CTC tea and flavored tea. Spices (whole) like jeera, saunf, dhania seeds, and black pepper. Seeds including mustard, sesame, cumin, and various mixed seeds. Namkeen and snack ingredients such as boondi, sev variants, and small crunchy items.

- PLC Control

- Electric

Cup Filler Machine Trade Information

- 10 Piece Per Month

- 7 Days

Product Description

A cup filler machine is an automatic volumetric filling system designed to pack free-flowing products such as sugar, salt, grains, pulses, tea, snacks, seeds, detergent powder, and granules with consistent accuracy. It operates using a set of adjustable measuring cups that dispense a fixed volume of product into each pouch. The machine ensures smooth product flow, uniform filling, and high-speed operation, making it ideal for medium to large-scale packaging needs. When integrated with a pouch-forming and sealing unit, the cup filler automatically measures, fills, seals, and cuts packets in one continuous process. Built with food-grade stainless-steel contact parts, easy-to-adjust cup volumes, and user-friendly controls, the cup filler machine delivers reliable performance, hygienic operation, and low maintenance, making it a preferred choice for granular and free-flow packaging applications.

Accurate and Versatile Filling Solutions

Equipped with a volumetric cup mechanism, the machine guarantees consistent weight and fill accuracy for a wide range of products, including sugar, salt, grains, pulses, spices, and seeds. Adjustable cup volumes make switching between products or pack sizes smooth and efficient, supporting small and bulk packaging without significant downtimes.

Robust Stainless-Steel Build and Hygienic Design

Contact parts are made of high-grade stainless steel, ensuring food safety and preventing contamination. The rust-proof, heavy-duty construction lends itself well to demanding industrial environments, enhancing operational longevity while maintaining hygiene standards.

User-Friendly Control and Efficient Operation

A user-centric PLC control panel enables operators to easily adjust settings and monitor the process in real-time. The electric drive system and heat-sealing technology streamline filling and sealing, making the machine suitable for high-speed, continuous operation with minimal supervision.

FAQ's of Cup Filler Machine:

Q: How does the automatic cup filler machine ensure accurate product measurement?

A: The machine utilizes a volumetric cup filling system that measures products precisely by volume, ensuring every pouch contains a consistent quantity. The cup sizes can be easily adjusted to fit different weight requirements, enhancing packaging uniformity.Q: What types of products can this filling machine handle?

A: This model is designed for free-flowing and granulated materials such as sugar, salt, grains (like rice and millets), pulses (e.g., chana dal, moong dal), tea, whole spices, seeds, and snack ingredients such as namkeen.Q: Where is the cup filler machine commonly used?

A: It is deployed in industrial packaging facilities, food processing units, and manufacturing plants throughout India, particularly where accurate and efficient bulk or consumer pouch filling is required.Q: How does the filling and sealing process work?

A: Products are dispensed through volumetric cups into pre-formed pouches or containers, which are then securely sealed using a heat-sealing technique. The entire process is monitored and managed via the PLC control system for ease and reliability.Q: What are the main benefits of using this cup filler machine?

A: Key advantages include high-speed filling (45-60 pouches/hour), reliability, minimal power consumption, low maintenance needs, and compliance with food-grade safety due to its stainless-steel contact parts.Q: When should the machine's cup volumes and settings be adjusted?

A: Cup volumes should be adjusted whenever there's a need to switch packaging weights or product types. The user-friendly control panel makes recalibrating settings quick and straightforward, with minimal interruption to production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email