- Home Page

- Company Profile

-

Our Products

- Industrial Packaging Machine

- pouch packing machine

- Collar Type Pouch Packing Machine

- Tea Pouch Packing Machine

- Single Head Automatic Packing Machine

- Pouch Filling Machine

- Fully Automatic Pouch Packing Machine

- 4 Head Linear Weight Filler

- Namkeen Packing Machine

- FFS Machine

- pneumatice Automatic Pouch Packing Machine

- Industrial Packing Machine

- Food Packaging Machine

- Milk Powder Packaging Machine

- Toys Gift Packing Machine

- Pepsi Pouch Packing Machine

- Pouch Packing Machine

- Rice Packaging Machines

- ORS Powder Pouch Packing Machine

- Kurkure Packing Machine

- BESAN POUCH PACKING MACHINE

- Granule Pouch Packing Machine

- Weighing Filling Machine For Spices

- Volumetric Cup Filler Machine

- Spice Pouch Packing Machine

- Flour Packing Machine

- Seed Packaging Machine

- Tea Pouch Packing Machine

- Pulses Packing Machine

- Tea Packing Machine

- Pneumatic Pouch Packing Machine

- Automatic Pouch Packing Machines

- Fully pneumatic pouch packing machine

- Packaging Machine

- Black Pepper Packaging Machine

- Granule Pouch Packing Machine

- Cup Filler Machine

- Tea Packing Machine

- Granules Packing Machine

- Potato Chips Packing Machine

- Wafers Packing Machine

- Sugar Packing Machine

- Potato Packing Machine

- Automatic Spice Powder Pouch Packing Machine

- STAINLESS STEEL SPICES POUCH PACKING MACHINE

- Snack Packing Machine

- Ice Cream Packaging Machine

- Automatic Detergent Powder Packing Machine

- Detergent Packaging Machine

- flour packing machine

- Banana Chips Packaging Machine

- Pneumatic Packing Machine with gift conveyor

- automatic Grain Packing Machine

- Snack Packing Machines

- Potato Packing Machine

- Single Head Weigher Pouch Packing Machine

- 4 Head Linear Weight Filler

- Chilli Powder Pouch Packing Machine

- Automatic Atta Packing Machines

- Vertical Form Fill Seal Machines

- Chikki Pouch Packing Machine

- Besan Packing Machine

- Four Head Weigher Packing Machine

- Automatic Murmura Packing Machines

- jally depositor Machine

- Bhujia Sev Packing Machine

- Popcorn Packing Machine

- Makhana Packing Machine

- Automatic Tea Packaging Machine

- Murmura Packing Machine

- Salt Packaging Machine

- Cup Filler Pouch Packing Machine

- Papad Packing Machine

- Candy Packaging Machine

- Flow Wrap Packaging Machines

- Automatic Spice Packaging Machine

- Multihead Weigher Packing Machine

- Powder Filling Machine

- Liquid Packaging Machine

- Stainless Steel Soap Bar Screw Conveyor

- Certificates

- Contact Us

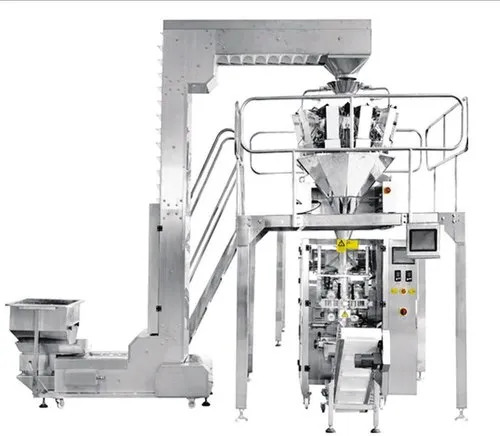

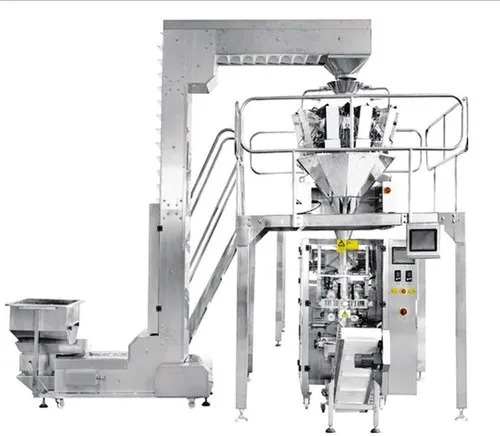

Multihead Weigher Machine

1450000.0 INR/Unit

Product Details:

- Usage Industrial

- Features -friendly touch screen interface for easy operation and monitoring. Contact parts made from food-grade materials Energy-efficient design for reduced operating costs. Robust construction for long-lasting durability. Customizable to various product types and fill weights. Advanced control system for precise filling and minimal product waste. High-speed and accuracy for optimal prodUseruction efficiency.

- Application Suitable for packaging granular products such as Wafers,Potato Chips,Banana Chips,poha, fryms, snacks, namkeen, pulses, tea, sugar, and salt.

- Filling Range 50-60

- Power Supply 440 volt

- Type Multi-Function Packaging Machines

- Material packaging machine

- Click to view more

X

Multihead Weigher Machine Price And Quantity

- 1 Unit

- 1450000.0 INR/Unit

Multihead Weigher Machine Product Specifications

- Electric

- 440 volt

- 1 year

- Multi-Function Packaging Machines

- 5.5kw Watt (w)

- -friendly touch screen interface for easy operation and monitoring. Contact parts made from food-grade materials Energy-efficient design for reduced operating costs. Robust construction for long-lasting durability. Customizable to various product types and fill weights. Advanced control system for precise filling and minimal product waste. High-speed and accuracy for optimal prodUseruction efficiency.

- Automatic

- 50-60

- Yes

- 25 Kilograms (kg)

- PLC Control

- Silver

- Durable, Highly Efficient, Less Power Consumable, Heavy Duty Machine, Rust Proof

- 220 Volt (v)

- Other

- Suitable for packaging granular products such as Wafers,Potato Chips,Banana Chips,poha, fryms, snacks, namkeen, pulses, tea, sugar, and salt.

- 50-60 Pcs/hr

- Industrial

- 800x100mm Millimeter (mm)

- Heat Sealing

- packaging machine

Multihead Weigher Machine Trade Information

- 4 Unit Per Month

- 15 Week

Product Description

A multi-head weigher machine is an advanced weighing system used in packaging lines to measure products quickly and accurately. It has multiple weighing heads arranged around a central point, and each head weighs a small amount of product. The machine then selects the best combination of weights to match the exact target weight. This helps companies pack products faster, reduce wastage, and maintain uniform quantity in every packet.

A multi-head weigher is a smart machine designed to weigh products with high precision. It contains several small weighing bowls that work together to calculate the perfect weight for each pack. The machine is commonly used for snacks, namkeen, dry fruits, seeds, candies, frozen items, and many other food products. Its speed and accuracy make it ideal for large-scale production.

Advanced Control and Efficiency

Equipped with PLC computerized controls and a user-friendly touchscreen interface, this Multihead Weigher Machine allows for seamless monitoring and operation. Its energy-efficient design and precise filling system help reduce product waste and operating costs, making it ideal for modern industrial packaging lines.

Versatile and Robust Construction

Built from durable, rust-proof materials, the packaging machine is suitable for a wide variety of granular products, including snacks and pulses. Its robust frame and food-grade contact parts guarantee long-term performance, reliability, and safety in fast-paced production environments.

FAQ's of Multihead Weigher Machine:

Q: How does the Multihead Weigher Machine increase packaging efficiency?

A: The machine uses an advanced PLC control system and multihead weighing technology to ensure precise measurement and rapid dispensing of products. Its high-speed and automated operation can handle up to 50-60 pieces per hour, reducing manual work and optimizing overall packaging productivity.Q: What types of products can be packaged with this machine?

A: This packaging machine is designed for a diverse range of granular items such as wafers, potato chips, banana chips, poha, fryms, snacks, namkeen, pulses, tea, sugar, and salt. Its customizable settings accommodate different product sizes and fill weights effortlessly.Q: When should I consider using this machine in my production line?

A: If your packaging requirements involve high volumes, consistent output, and minimal product loss, this Multihead Weigher Machine is ideal. It is best suited for industrial environments where reliable, high-speed, and accurate packaging is crucial.Q: Where is the Multihead Weigher Machine commonly installed?

A: It is typically installed in large-scale food processing and packaging facilities, snack manufacturing plants, or any industrial setting in India that packages granular food items or similar products needing rapid and precise weighing and packing.Q: What is the process of operating the machine?

A: Operation is straightforward-simply load the product, set the desired fill parameters on the touchscreen interface, and start the machine. The PLC system controls the weighing, filling, and heat sealing processes automatically, ensuring hygienic and efficient packaging with minimal supervision.Q: What are the main benefits of using this weigher machine?

A: Key benefits include accurate and consistent filling, user-friendly controls, heavy-duty construction, reduced product waste, lower power consumption, rust-proof materials for longevity, and quick-change adaptability to different product types, boosting productivity and product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email