- Home Page

- Company Profile

-

Our Products

- Industrial Packaging Machine

- pouch packing machine

- Collar Type Pouch Packing Machine

- Tea Pouch Packing Machine

- Single Head Automatic Packing Machine

- Pouch Filling Machine

- Fully Automatic Pouch Packing Machine

- 4 Head Linear Weight Filler

- Namkeen Packing Machine

- FFS Machine

- pneumatice Automatic Pouch Packing Machine

- Industrial Packing Machine

- Food Packaging Machine

- Milk Powder Packaging Machine

- Toys Gift Packing Machine

- Pepsi Pouch Packing Machine

- Pouch Packing Machine

- Rice Packaging Machines

- ORS Powder Pouch Packing Machine

- Kurkure Packing Machine

- BESAN POUCH PACKING MACHINE

- Granule Pouch Packing Machine

- Weighing Filling Machine For Spices

- Volumetric Cup Filler Machine

- Spice Pouch Packing Machine

- Flour Packing Machine

- Seed Packaging Machine

- Tea Pouch Packing Machine

- Pulses Packing Machine

- Tea Packing Machine

- Pneumatic Pouch Packing Machine

- Automatic Pouch Packing Machines

- Fully pneumatic pouch packing machine

- Packaging Machine

- Black Pepper Packaging Machine

- Granule Pouch Packing Machine

- Cup Filler Machine

- Tea Packing Machine

- Granules Packing Machine

- Potato Chips Packing Machine

- Wafers Packing Machine

- Sugar Packing Machine

- Potato Packing Machine

- Automatic Spice Powder Pouch Packing Machine

- STAINLESS STEEL SPICES POUCH PACKING MACHINE

- Snack Packing Machine

- Ice Cream Packaging Machine

- Automatic Detergent Powder Packing Machine

- Detergent Packaging Machine

- flour packing machine

- Banana Chips Packaging Machine

- Pneumatic Packing Machine with gift conveyor

- automatic Grain Packing Machine

- Snack Packing Machines

- Potato Packing Machine

- Single Head Weigher Pouch Packing Machine

- 4 Head Linear Weight Filler

- Chilli Powder Pouch Packing Machine

- Automatic Atta Packing Machines

- Vertical Form Fill Seal Machines

- Chikki Pouch Packing Machine

- Besan Packing Machine

- Four Head Weigher Packing Machine

- Automatic Murmura Packing Machines

- jally depositor Machine

- Bhujia Sev Packing Machine

- Popcorn Packing Machine

- Makhana Packing Machine

- Automatic Tea Packaging Machine

- Murmura Packing Machine

- Salt Packaging Machine

- Cup Filler Pouch Packing Machine

- Papad Packing Machine

- Candy Packaging Machine

- Flow Wrap Packaging Machines

- Automatic Spice Packaging Machine

- Multihead Weigher Packing Machine

- Powder Filling Machine

- Liquid Packaging Machine

- Stainless Steel Soap Bar Screw Conveyor

- Certificates

- Contact Us

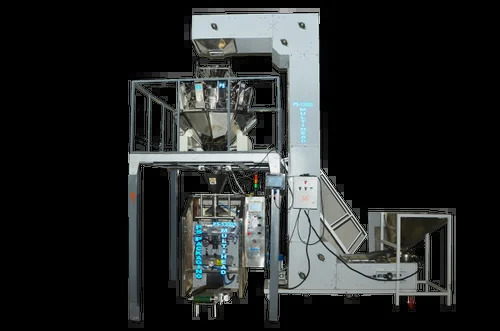

automatic Grain Packing Machine

375000.0 INR/Piece

Product Details:

- Features Contact parts made from food-grade materials Energy-efficient design for reduced operating costs. Compact footprint to optimize floor space. Robust construction for long-lasting durability. Customizable to various product types and fill weights. Advanced control system for precise filling and minimal product waste. Compliance with industry standards for safety and hygien.

- Power Supply 220 volt

- Filling Range 30-40

- Usage Industrial

- Application Snacks,Fryms,Tea,Suger and all types granular items. Easy to operate and maintain

- Type Filling Machine

- Material Mild Steel

- Click to view more

X

automatic Grain Packing Machine Price And Quantity

- 1 Piece

- 375000.0 INR/Piece

automatic Grain Packing Machine Product Specifications

- Silver

- PLC Control

- 1 year

- Contact parts made from food-grade materials Energy-efficient design for reduced operating costs. Compact footprint to optimize floor space. Robust construction for long-lasting durability. Customizable to various product types and fill weights. Advanced control system for precise filling and minimal product waste. Compliance with industry standards for safety and hygien.

- 220-240 Volt (v)

- Electric

- 30-40 Pcs/hr

- Automatic

- Yes

- 3.5kw Volt (v)

- 30-40

- 220 volt

- Other

- Snacks,Fryms,Tea,Suger and all types granular items. Easy to operate and maintain

- Mild Steel

- Heat Sealing

- Industrial

- Filling Machine

- Highly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

automatic Grain Packing Machine Trade Information

- 10 Piece Per Month

- 7 Days

Product Description

An automatic grain packaging machine is a high-efficiency system designed to fill and pack grains such as rice, wheat, pulses, millets, corn, and other free-flowing products with precision. The machine automatically weighs, fills, and seals each pouch without manual intervention, ensuring consistent accuracy and hygienic handling. Using advanced weighing technologyeither a cup filler, screw feeder, or weighing scaleit delivers uniform pack weights and minimizes product wastage. The machine forms pouches from roll film, fills the measured grain, seals the packet, and cuts it into individual packs, enabling continuous high-speed production. Built with durable stainless-steel contact parts and user-friendly controls, the automatic grain packaging machine is ideal for grain mills, food processing units, and bulk suppliers looking for reliable, fast, and clean packaging operations.

Advanced Automation with User-Friendly Operation

Equipped with a computerized PLC control system, this machine streamlines packaging with minimal human intervention. Its intuitive interface allows easy adjustments to accommodate different product types and fill weights, offering unmatched flexibility. Automatic operation reduces manual effort and ensures consistent output quality, making it accessible even to operators with basic technical skills.

Optimized Design for Industrial Needs

Engineered from durable mild steel and finished in rust-proof silver, the machine features a robust construction ideally suited for demanding industrial use. With a compact footprint, it optimizes floor space while maintaining high packing efficiency. Heavy-duty components guarantee long-term reliability, while energy-efficient mechanisms help reduce operational costs, boosting your production's bottom line.

FAQ's of automatic Grain Packing Machine:

Q: How does the automatic grain packing machine operate and manage filling accuracy?

A: The machine uses a computerized PLC control system that ensures precision during the filling process. Operators can easily set fill weights and select product types on the control panel, enabling accurate and consistent packing for items like snacks, tea, and sugar.Q: What products can this packing machine handle effectively?

A: This machine is designed to package a broad range of granular products such as snacks, fryms, tea, sugar, and other similar items, thanks to its adjustable filling range and customizable features.Q: When is the right time to maintain or service the machine?

A: Routine maintenance is streamlined due to the machine's easy-to-operate design. It's recommended to follow the manufacturer's service schedule or conduct basic maintenance checks after every production cycle to ensure optimal performance.Q: Where is this machine suitable for installation?

A: Ideally suited for industrial environments, the machine's compact and robust design allows for easy integration even in spaces with limited floor area. Its durable construction ensures dependable use wherever industrial packaging is required.Q: What is the process for packing products using this machine?

A: Products are poured into the machine's hopper, after which the advanced PLC system manages accurate weight-based dispensing into pouches. The heat sealing feature then secures the packaging, ensuring the contents are protected and tamper-resistant.Q: How does the machine benefit manufacturers in terms of cost and efficiency?

A: With energy-efficient components, reduced product waste due to precise filling, and low power consumption (just 3.5kw), this machine offers significant savings. Its high output speed and durable build lead to lower maintenance costs and extended operational life.Q: What assurance of reliability and safety does the machine offer?

A: Compliant with recognized industry standards for safety and hygiene, the machine features food-grade contact parts, reliable heat sealing, and a one-year warranty from the manufacturer, ensuring peace of mind and dependable operation for your packaging needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email